Introduction

Heavy machinery power cables play a crucial role in the operation of industrial equipment and machinery. These cables are designed to deliver electrical power to large machines such as cranes, excavators, bulldozers, and other heavy equipment used in construction, mining, and various other industries. The reliability and efficiency of these power cables are essential for ensuring the seamless operation of heavy machinery, as any malfunction or failure can result in costly downtime and delays in production. In this article, we will explore the importance, functionality, and key considerations of heavy machinery power cables in industrial operations.

Importance of Heavy Machinery Power Cables

Heavy machinery power cables are essential components of industrial operations for several reasons:

1. Power Transmission: Heavy machinery requires a significant amount of electrical power to operate efficiently. Power cables are responsible for transmitting high voltage electricity from the power source to the machinery, enabling them to perform their designated tasks.

2. Safety: Properly designed and maintained power cables are crucial for maintaining a safe working environment. Faulty or damaged cables can pose serious safety risks, such as electrical shocks, fires, and equipment damage. Ensuring the integrity of power cables is essential for preventing accidents and injuries in industrial settings.

3. Reliability: Industrial operations rely heavily on the continuous and uninterrupted operation of heavy machinery. Power cables must be durable and reliable to withstand the harsh conditions and heavy loads that industrial equipment often encounters. A failure in the power cable can result in costly downtime and production losses.

4. Efficiency: Efficient power transmission is essential for optimizing the performance of heavy machinery. High-quality power cables with low resistance ensure that electricity is delivered efficiently, reducing energy wastage and improving overall operational efficiency.

Functionality of Heavy Machinery Power Cables

Heavy machinery power cables are designed to withstand the demanding conditions of industrial environments and provide reliable power transmission to heavy equipment. The functionality of these cables is determined by various factors, including:

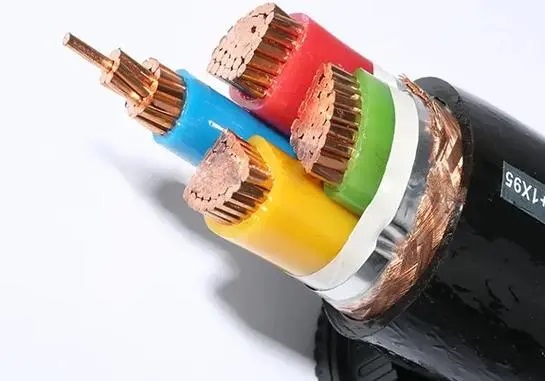

1. Cable Construction: Heavy machinery power cables are typically constructed with multiple layers of insulation, shielding, and protective jackets to ensure durability and safety. The conductors inside the cable are made of high-quality materials such as copper or aluminum to facilitate efficient power transmission.

2. Voltage Rating: Heavy machinery power cables are available in different voltage ratings to accommodate the specific power requirements of industrial equipment. It is essential to select a cable with the appropriate voltage rating to ensure safe and reliable operation.

3. Current Capacity: The current-carrying capacity of a power cable is determined by factors such as conductor size, insulation material, and ambient temperature. Heavy machinery power cables are designed to handle high current loads without overheating or sustaining damage.

4. Flexibility: Flexibility is a critical factor in heavy machinery power cables, as they often need to be routed through tight spaces or around moving parts of machinery. Flexible cables are easier to install and maintain, reducing the risk of cable damage and improving overall system performance.

5. Environmental Resistance: Industrial environments can expose power cables to various harsh conditions, including extreme temperatures, moisture, chemicals, and mechanical stress. Heavy machinery power cables are designed to resist these environmental factors and maintain their performance and integrity over time.

Key Considerations for Selecting Heavy Machinery Power Cables

When selecting heavy machinery power cables for industrial applications, several key considerations must be taken into account to ensure optimal performance and safety:

1. Voltage and Current Rating: Determine the voltage and current requirements of the machinery to select a power cable with the appropriate rating. Using Control cable applications with insufficient capacity can lead to overheating and equipment failure.

2. Cable Size and Length: Choose the correct cable size and length to minimize voltage drop and ensure efficient power transmission. Oversized cables can be costly and difficult to install, while undersized cables can lead to performance issues.

3. Insulation and Jacketing: Insulation and jacketing materials play a crucial role in protecting the conductors from environmental factors and mechanical damage. Select cables with high-quality insulation and jacketing materials that are suitable for the intended application.

4. Environmental Compatibility: Consider the environmental conditions in which the power cables will be installed, such as temperature, moisture, and chemical exposure. Choose cables that are designed to withstand these conditions and maintain their performance over time.

5. Compliance with Standards: Ensure that the selected power cables comply with industry standards and regulations for electrical safety and performance. Using non-compliant cables can pose serious risks to personnel and equipment.

6. Installation and Maintenance: Proper installation and maintenance are essential for ensuring the longevity and efficiency of heavy machinery power cables. Follow manufacturer guidelines for installation practices and conduct regular inspections to detect any signs of wear or damage.

Conclusion

Heavy machinery power cables are indispensable components of industrial operations, providing the essential electrical power needed to operate heavy equipment efficiently and safely. Understanding the importance, functionality, and key considerations of these cables is crucial for ensuring the reliability and performance of industrial machinery. By selecting high-quality power cables that meet the specific requirements of the application and following best practices for installation and maintenance, industrial operators can minimize downtime, improve operational efficiency, and enhance overall workplace safety.